Preheating Touch Screen BGA Rework Machine

Hija ideali biex tissostitwixxi komponenti żgħar fuq smartphones mingħajr ma ssir ħsara lil konnetturi fil-qrib u partijiet oħra tal-plastik.

Deskrizzjoni

Preheating Touch Screen BGA Rework Machine

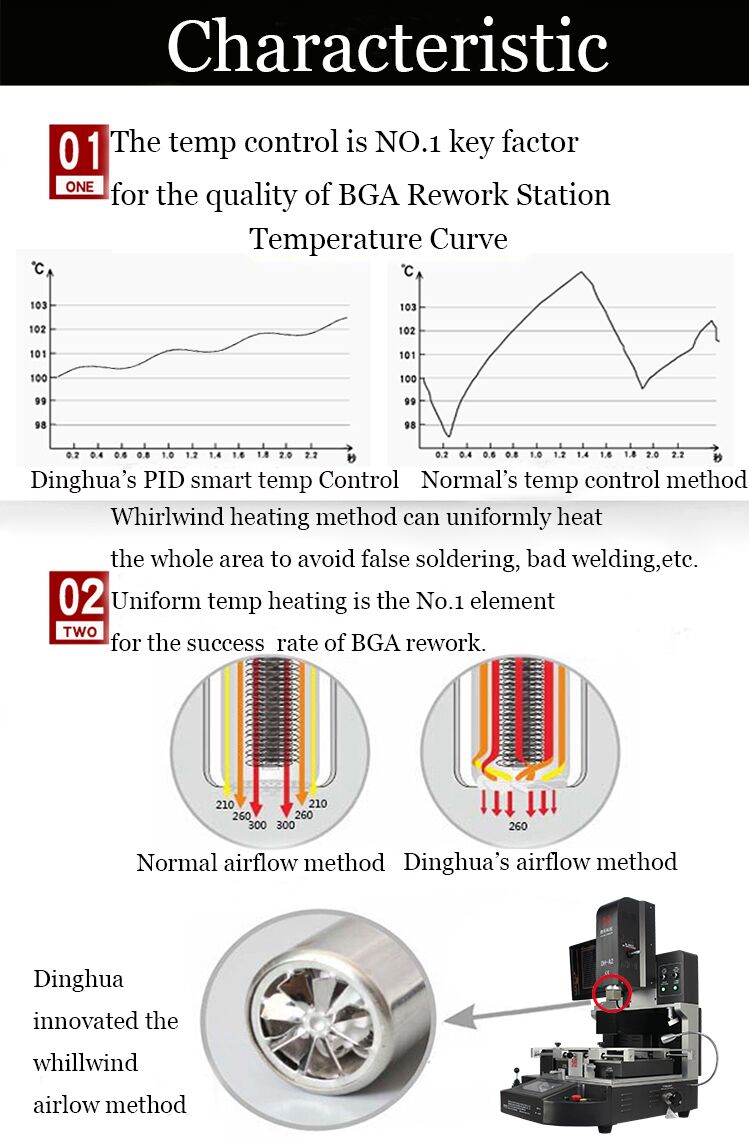

1. Karatteristiċi tal-Prodott ta 'Preheating Touch Screen BGA Rework Machine

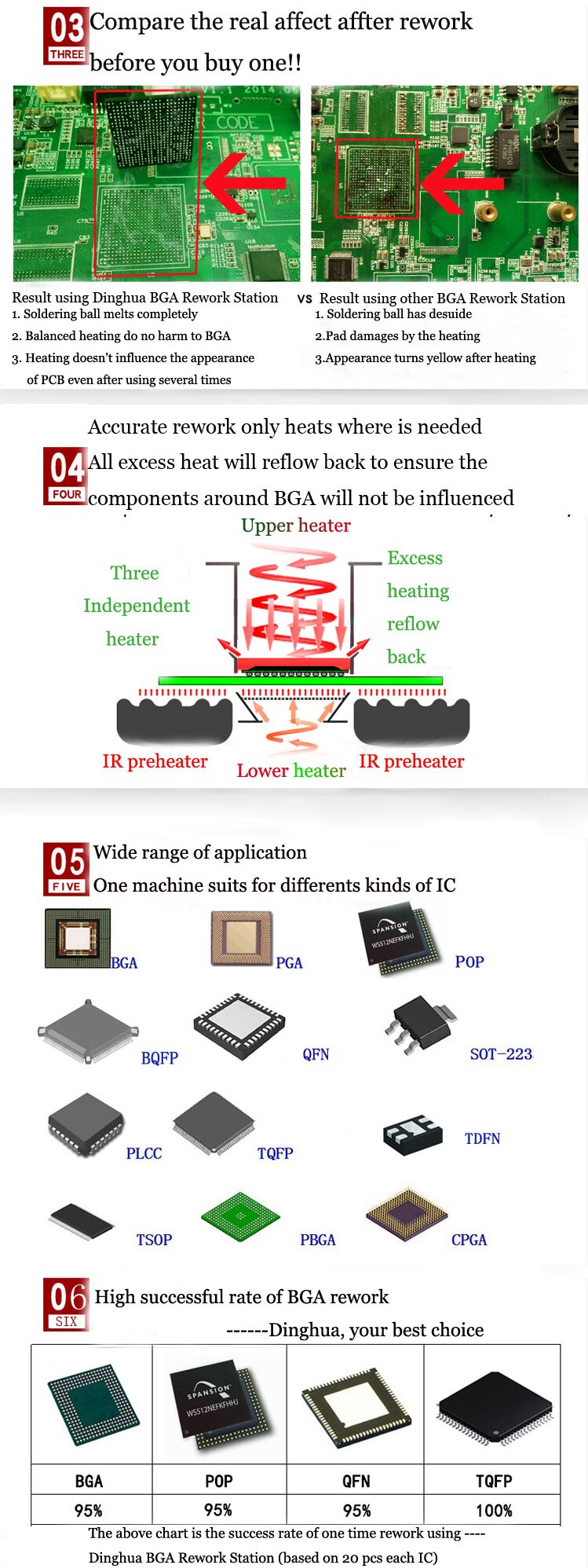

Iż-żoni tat-temperatura ta 'fuq u ta' isfel jisħnu b'mod indipendenti, Fann ta 'fluss inkroċjat jiksaħ malajr biex jipproteġi l-PCB minn

deformazzjoni waqt l-iwweldjar.

2. Għal kapaċità termali kbira ta 'PCB jew rekwiżiti oħra ta' iwweldjar b'temperatura għolja u mingħajr ċomb, kollha jistgħu jkunu

immaniġġjat faċilment.

3. Il-monitoraġġ tal-Pre-Heater jipprevjeni operatur milli jibda profil meta l-heater ma jkunx lest.

4. Pre-Heater jista' jintefa jew jitqiegħed fis-SetBack meta s-sistema ma tkunx qed tintuża.

Vacuum pik bena fl-aġġustament theta għall-ippożizzjonar faċli tal-komponenti.

5. Wara li l-BGA tneħħi u l-istann ikollha funzjoni ta 'allarm tal-vuċi.

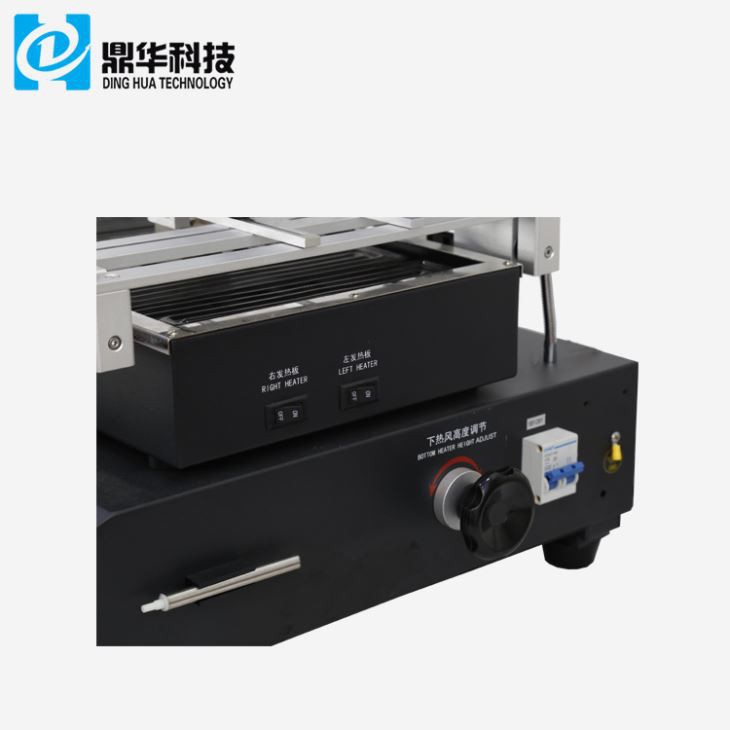

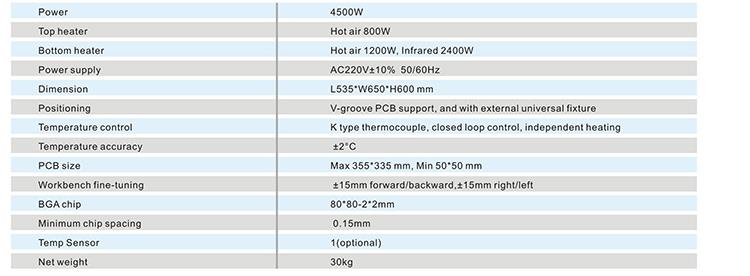

3.Speċifikazzjoni ta 'Preheating Touch Screen BGA Rework Machine

4.Dettalji ta 'Preheating Touch Screen BGA Rework Machine

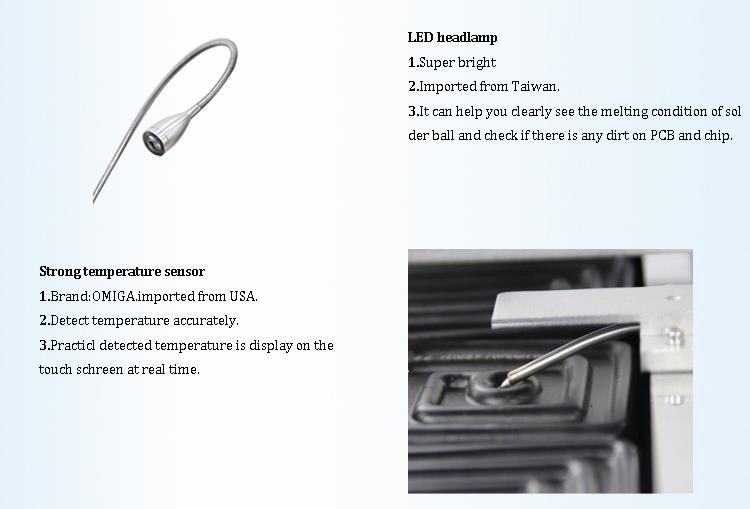

1. HD Touch screen interface;

2.Three ħiters indipendenti (arja sħuna & infra-aħmar);

3. Pinna tal-vakwu;

4.Lampa ta 'quddiem Led.

5.Għaliex Agħżel il-Magni mill-ġdid tagħna tat-Touch Screen BGA tat-tisħin minn qabel?

6.Ċertifikat ta 'Preheating Touch Screen BGA Rework Machine

7.Packing & Ġarr ta 'Preheating Touch Screen BGA Rework Machine

8.Għarfien relatat

Proċess imħallat b'żewġ naħat ta 'SMT

A: incoming inspection => PCB's B-side patch glue => patch => curing => flap => A-side PCB plug => wave soldering =>

cleaning => test =>xogħol mill-ġdid

Post-paste l-ewwel, adattat għal komponenti SMD aktar minn komponenti diskreti

B: incoming inspection => PCB A-side insert (pinning) => flap => PCB B-side spot adhesive => patch => curing => flap =>

wave soldering => cleaning => Test =>Rework Post-inserzjoni u post-fitting, adattati biex jisseparaw aktar komponenti

minn komponenti SMD

C: incoming material inspection => PCB's A surface silk screen solder paste => patch =>

drying => reflow soldering => plug-in, pin bending => flap => PCB B surface patch glue => Patch => Curing => Flap =>

Wave Soldering => Cleaning => Detection =>Rework A wiċċ imħallat, B wiċċ impunjazzjoni. ?

D: incoming inspection => PCB's B side spot adhesive => patch => curing => flap =>PCB's A side silk screened solder pasta

=> patch => A side reflow => plug-in => B-side wave soldering => cleaning => test =>xogħol mill-ġdid A-side taħlit, B-side immuntar.

L-ewwel SMD, reflow, post-fabbrikazzjoni, issaldjar tal-mewġ

E: incoming inspection => PCB side B silk screen solder paste (point mount glue) => patch => drying (curing) => reflow soldering =>

flap => PCB side A silk screen solder paste => Patch => Drying = Reflow soldering 1 (local soldering can be used) => Plug-in =>

Wave soldering 2 (If there are few components, you can use manual soldering) => Cleaning => Test =>Aħdem mill-ġdid Muntaġġ tal-wiċċ,

B wiċċ imħallat.